|

|

|

M Wright & Sons Ltd, New automatic weaving looms, January 1947

Loughborough Echo, Friday, 31st January 1947

Invention by Quorn man

New automatic weaving looms

Messrs. M Wright & Sons Ltd

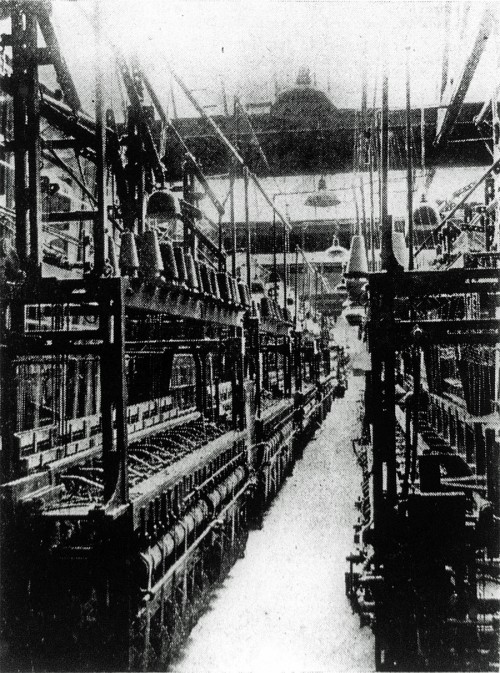

Using scrap iron, old castings and obsolete machinery re-modelled, Messrs M Wright and Sons Ltd, Quorn, have built 50 new automatic weaving looms, which turn out more work than the 180 old-fashioned looms which have been removed.

The new loom is known as the "W" loom and was invented by Mr. W. Williamson, of Quorn. formerly of Barrow-on-Soar, during the war. The machines are built entirely at the Quorn premises and are now patented all over the world. Many enquiries have been received, but no orders will be met until the firm's own requirements have been satisfied.

Coupled with this notable advance in automatic weaving, Messrs. Wright and Sons are in the middle of a big 'rebuilding scheme at their Quorn factory, which is giving the operatives tremendously improved working conditions in doing away with dark, cramped and unsuitable shops.'

Highly praised by textile machine experts, the new "W" smallware loom makes high quality productions on standard lines, with better edge formation and simple but efficient mechanism.

The loom makes all kinds of elastic and rigid webs for braces, corsets, garters, suspenders, etc., and most of the work produced is being exported and thus helping the country financially.

BIG STRIDE FORWARD

Progress in the mechanical side of smallware weaving has not been as rapid as in the wide weaving section of the industry and the "W" loom represents a big stride for-ward in this direction.

Comparison between the ordinary loom and the "W" loom shows that 50 weavers are required for 100 ordinary looms, each with 20 webs, representing 2,000 webs, whereas with the "W" loom 28 weavers can work 168 looms each of 12 webs, representing 1,992 webs.

On the production side 125 pieces are produced from ' one 12-piece loom, compared with 100 pieces from one 20-piece loom, in the same time. The efficiency of the new loom has averaged between 65 and 72 per cent., compared with 45 per cent. for elastic brace webs.

Another great advantage is that the new loom is within the capacity of the ordinary loom mechanic, both erection and maintenance, after small experience, and the labour problem is simplified. Young people of 15 years and over can be placed in charge of a number of looms within a few weeks and the high wages which can be earned are a great incentive.

Mr. Williamson, who has worked at Wright's for 30 years and is now head of the machine shop, told an Echo reporter who saw the machines in operation this week, "We also have our own ideas about the machinery which goes with the looms and we are trying to make working conditions better all round. Before the war, up to 18 months was spent in learning weaving; now a worker can be left on her own in two months and be quite happy."

Wright's make webs and cloth up to 60 inches wide, the latter being manufactured on a Swiss loom, the only one of its kind in this country. The output of the factory before the war was mainly narrow webs, but they have since gone in for wider products (up to 18 inches wide the material is known as "web", over that width as "cloth").

An interesting find was made recently when some rubber rollers were being scrapped. In the centre of one of the wood rollers was the following written in pencil: "June 25, 1862, John Fisher, Common Grocer, Abbey Mills, Leicester."

WORK FOR FORCES

Some of the old looms at Wright's have been in use since the factory was established by Mr. Philip Wright. With old and new looms an astronomical quantity of material was made for the Forces during the war.

Mr. L. Robey, of Quorn, now weaving manager after 40 years at Wright's, said to our reporter, " We have made it our study to give young people a sound and practical training. We look after them in every way we can." Workers travel daily to the factory from local villages and from places as far away as Leicester, Coalville, Thringstone and East Leake.

Young workers get special concessions in canteen prices, are encouraged in every way possible to follow' textiles as a career and may borrow from a textile library at the factory. Trade union and welfare conditions are of a high standard and soon all the employees will enjoy the benefits of a five-day week, at present in force only for youngsters.

Below is a view of the new weaving looms.

| |

|

|

|

Submitted on: |

2019-12-17 |

|

Submitted by: |

Sue Templeman |

|

Artefact ID: |

2253 |

|

Artefact URL: |

www.quornmuseum.com/display.php?id=2253 |

|

Print: |

View artefact in printer-friendly page or just on its own (new browser tab). |

|

|

|

|

|